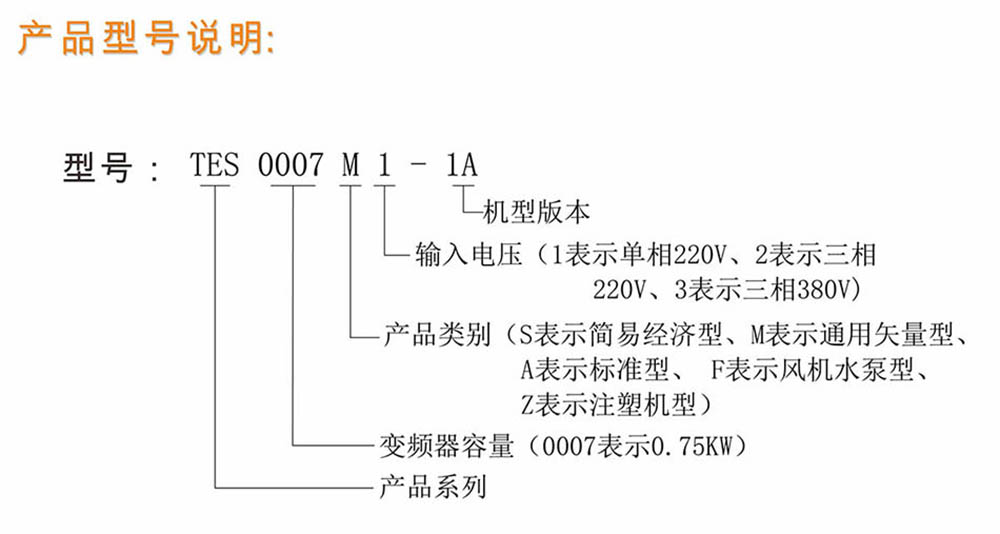

TES Frequency Converter(0.75KW)

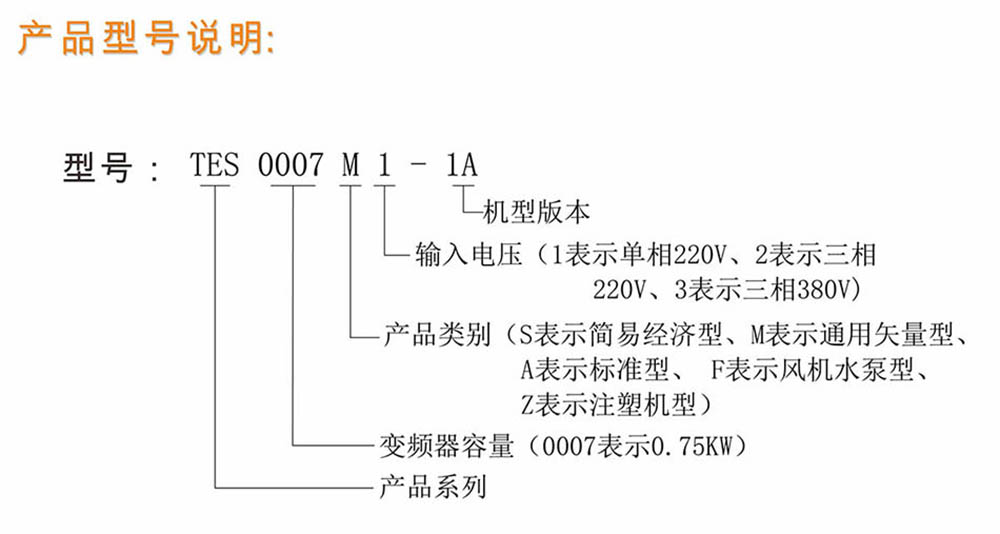

Model: TES007M21A, TES007M43B

Voltage: 220V/380V

Power: 0.75KW

Phase number: single-phase/three-phase

Voltage: 220V/380V

Power: 0.75KW

Phase number: single-phase/three-phase

OEM technical

Support

Loading

capacity 35KG

Monthly capacity

1000000 sets

50000 times

cycle test

Quiet and

smooth sliding

Product Details

Product Features:

From design and development to production and manufacturing, every link of the TES500 series frequency converter aims to achieve reliability, ease of operation and economy of the product.

Reliability

1. Professional assembly line, featuring a three-proof paint treatment process that is dust-proof, moisture-proof and mold-proof, as well as a complete 8S management system! Advanced process flow control, standardized operation procedures, and professional product testing equipment ensure that TESECH users receive satisfactory products and technical services.

2. The entire series adopts Siemens IGBT as the core to ensure high-quality performance. With large-scale motor control IC+IGBT as the core, it features multiple protection functions and has high overall reliability. The full series of independent air duct design greatly enhances the reliability of the frequency converter during long-term operation in application environments such as textile, printing and dyeing, papermaking, wire drawing, and cement.

3. By adopting an adaptive optimized spatial voltage vector algorithm, ideal sinusoidal waveforms can be output in all frequency bands, ensuring the reliable operation of the motor. It has strong adaptability to the incoming line voltage, with fluctuations up to ±20%, and is particularly suitable for areas with poor power grid quality.

4. By dynamically controlling the DC bus voltage, high-frequency rapid shutdown and power-off without shutdown control can be achieved. Perfect protection functions: It provides users with as many as 18 fault protection functions, which can achieve all-round protection from frequency converters to motors.

Easy to operate:

(1) The user menu for parameter setting is well-structured and clear, with convenient and quick query and modification. The operation is simple and easy to start quickly. The cooling fan is easy to disassemble and assemble, and convenient for maintenance.

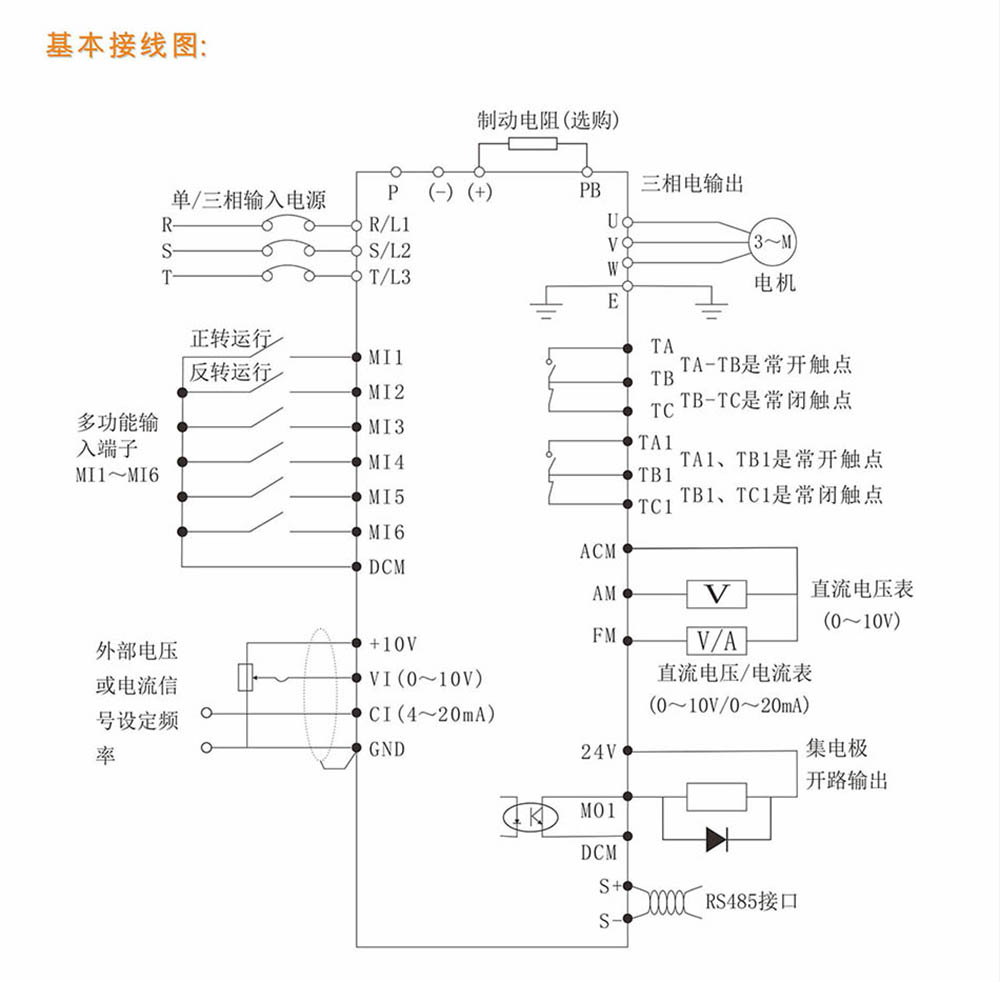

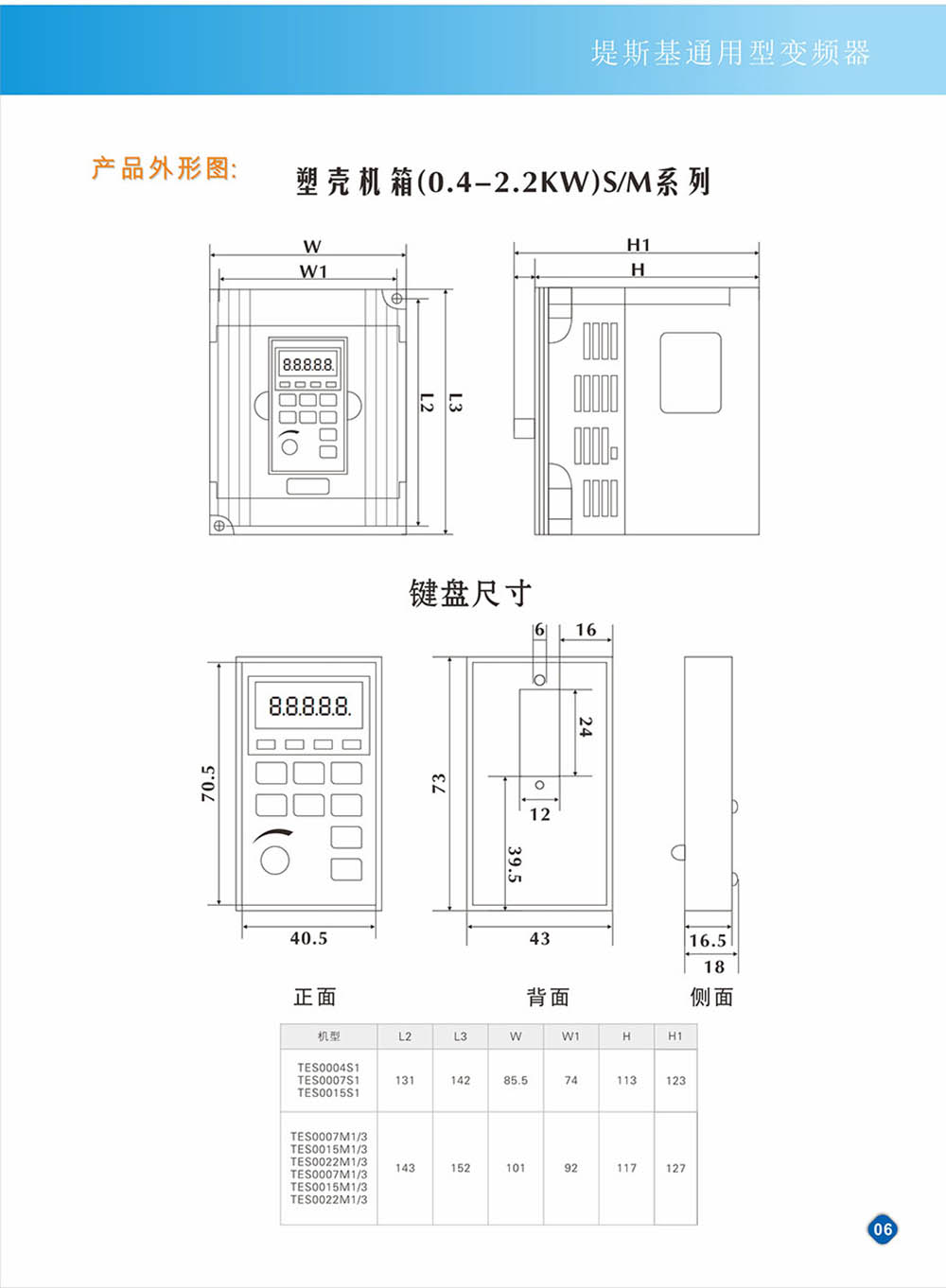

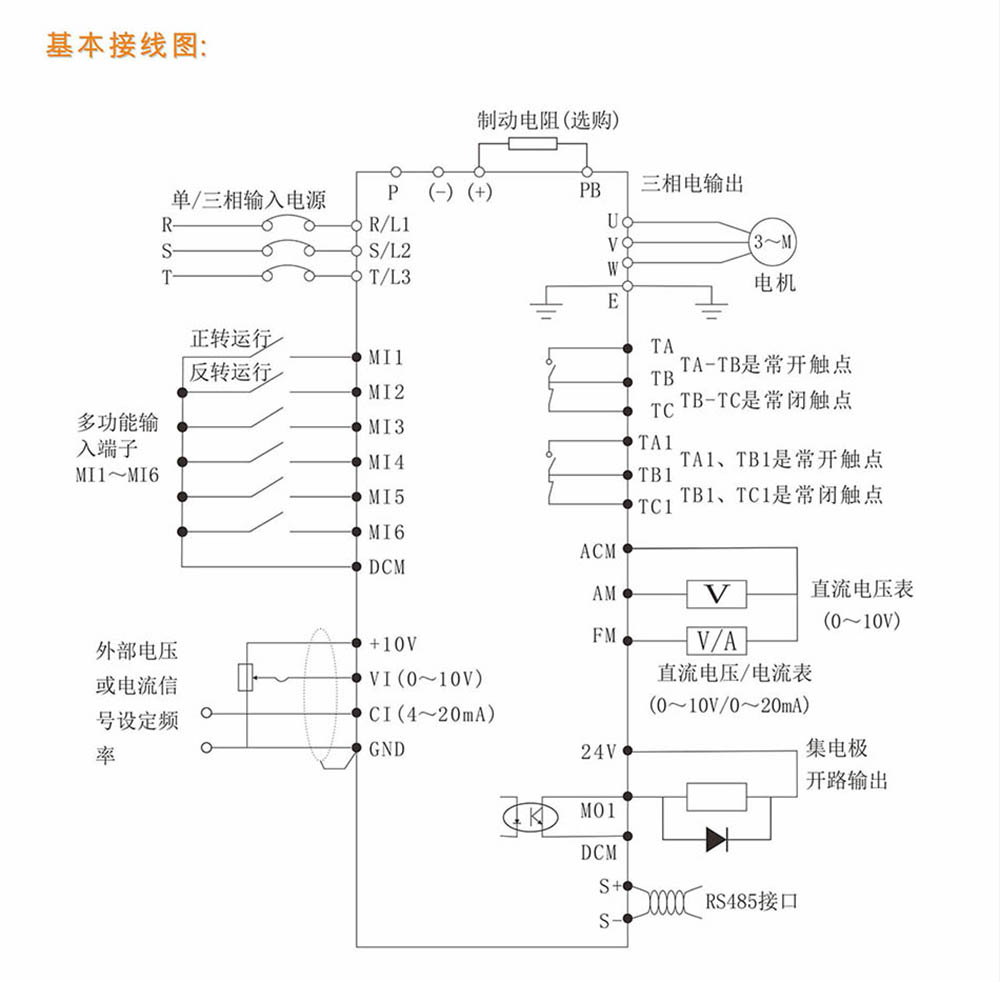

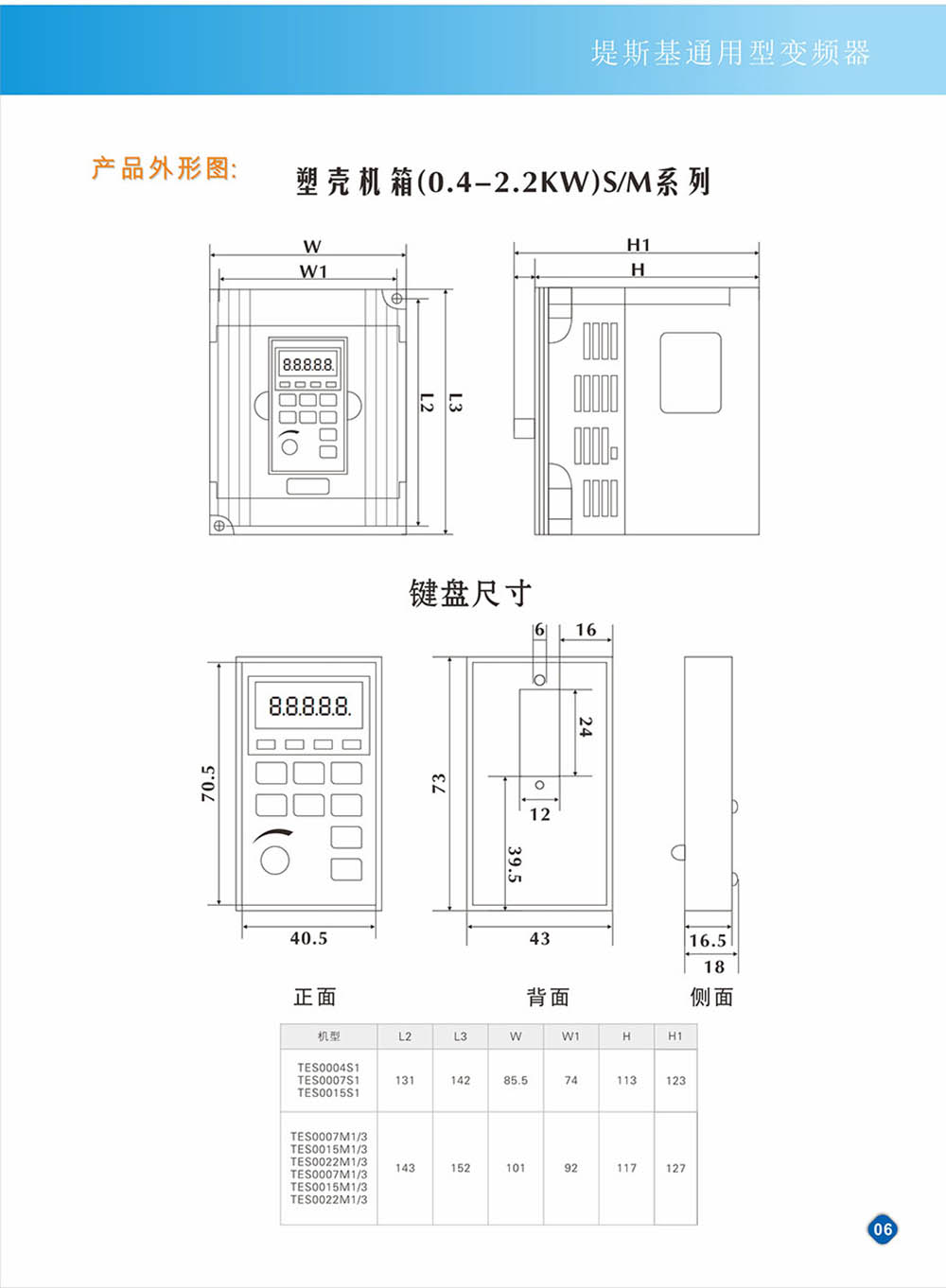

(2) It adopts an upper and lower wiring method, featuring a compact structure, convenient installation, rich and flexible input and output interfaces, and strong versatility in control methods, thus saving energy.

The installation space is spacious and the appearance is beautiful.

(3) Two-wire/three-wire start and stop control mode, convenient for users to operate;

(4) Strong overload capacity, 150% (60S), 180% (0.2S);

(5) Built-in PD regulator, which can conveniently form closed-loop control;

(6) Communication interface :RS485 communication interface. TESECH adopts ModbusRTU as the standard communication protocol.

(7) Speed tracking function fully implemented by software;

(8) User password protection Settings: It can protect the parameters set by users and prevent non-professionals from modifying them.

(9) Convenient and practical LED operation panel: Facilitates customer monitoring and debugging.

Economy:

① We have achieved a large-scale assembly line production mode, with comprehensive and strict process management and a complete cost control management system.

② Modular design, standardization, large-scale production, and high-efficiency enterprise operation have effectively reduced operating costs, giving the company's products a strong cost advantage.

③ Built-in braking unit for models below 18.5KW.

From design and development to production and manufacturing, every link of the TES500 series frequency converter aims to achieve reliability, ease of operation and economy of the product.

Reliability

1. Professional assembly line, featuring a three-proof paint treatment process that is dust-proof, moisture-proof and mold-proof, as well as a complete 8S management system! Advanced process flow control, standardized operation procedures, and professional product testing equipment ensure that TESECH users receive satisfactory products and technical services.

2. The entire series adopts Siemens IGBT as the core to ensure high-quality performance. With large-scale motor control IC+IGBT as the core, it features multiple protection functions and has high overall reliability. The full series of independent air duct design greatly enhances the reliability of the frequency converter during long-term operation in application environments such as textile, printing and dyeing, papermaking, wire drawing, and cement.

3. By adopting an adaptive optimized spatial voltage vector algorithm, ideal sinusoidal waveforms can be output in all frequency bands, ensuring the reliable operation of the motor. It has strong adaptability to the incoming line voltage, with fluctuations up to ±20%, and is particularly suitable for areas with poor power grid quality.

4. By dynamically controlling the DC bus voltage, high-frequency rapid shutdown and power-off without shutdown control can be achieved. Perfect protection functions: It provides users with as many as 18 fault protection functions, which can achieve all-round protection from frequency converters to motors.

Easy to operate:

(1) The user menu for parameter setting is well-structured and clear, with convenient and quick query and modification. The operation is simple and easy to start quickly. The cooling fan is easy to disassemble and assemble, and convenient for maintenance.

(2) It adopts an upper and lower wiring method, featuring a compact structure, convenient installation, rich and flexible input and output interfaces, and strong versatility in control methods, thus saving energy.

The installation space is spacious and the appearance is beautiful.

(3) Two-wire/three-wire start and stop control mode, convenient for users to operate;

(4) Strong overload capacity, 150% (60S), 180% (0.2S);

(5) Built-in PD regulator, which can conveniently form closed-loop control;

(6) Communication interface :RS485 communication interface. TESECH adopts ModbusRTU as the standard communication protocol.

(7) Speed tracking function fully implemented by software;

(8) User password protection Settings: It can protect the parameters set by users and prevent non-professionals from modifying them.

(9) Convenient and practical LED operation panel: Facilitates customer monitoring and debugging.

Economy:

① We have achieved a large-scale assembly line production mode, with comprehensive and strict process management and a complete cost control management system.

② Modular design, standardization, large-scale production, and high-efficiency enterprise operation have effectively reduced operating costs, giving the company's products a strong cost advantage.

③ Built-in braking unit for models below 18.5KW.